Initiatives for Achieving Carbon Neutrality

Initiatives on De-carbonization, Recycling-oriented Business

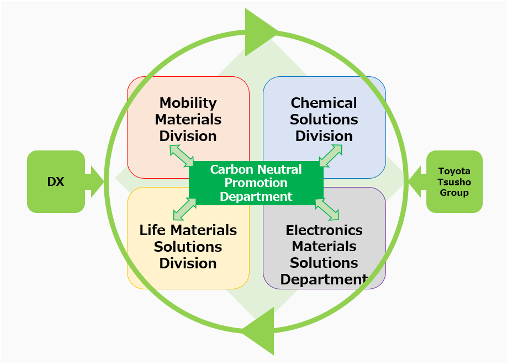

As a member of the Toyota Tsusho Group, we act in accordance with its policy on carbon neutrality.

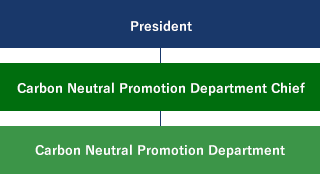

In addition, we established the Carbon Neutral Promotion Department in April 2022 to advance our activities and accelerate initiatives for contributing to a shift to a decarbonized society.

This department acts as an organization bridging the Corporate Division and Sales Divisions, aiming to reduce the whole of our GHG emissions from the overall supply chain by the reduction of Scope 3 emissions in the value chain, in cooperation with our suppliers and customers.

Promotion Structure

Initiatives on De-carbonization, Recycling-oriented Business

In addition to handling chemical products derived from non-fossil sources, we aim to create a system that reinterprets products and raw materials that have been “discarded” as new “resources” and recirculates them.

Leveraging our strengths in mobility materials, as well as in life materials, chemicals, and electronics materials, we will provide optimal proposals to our customers while utilizing our DX and R&D teams.

Furthermore, we participate an initiative called “The Green Transformation League (commonly known as “the GX League” in Japan)” which is organized by the Ministry of Economy, Trade and Industry, and we are committed to continuously reducing our own GHG emissions. Through our business activities, we also strive to reduce GHG emissions across the entire supply chain, contributing to Japan’s goal of achieving carbon neutrality.

Initiatives on Carbon Neutral and Recycling Businesses

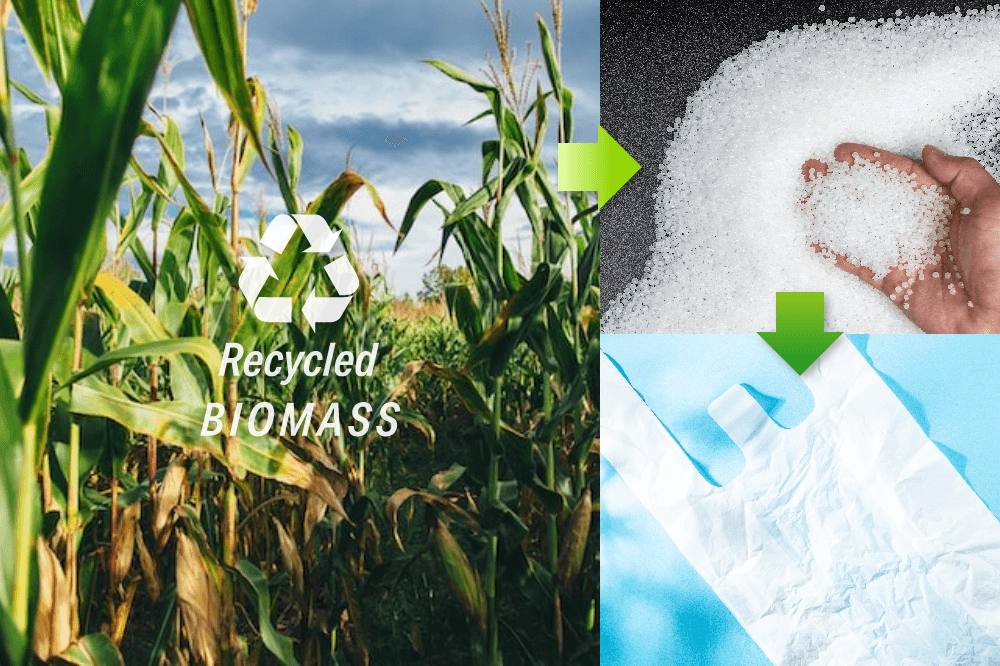

Import and sale of various types of bio-based materials (polyethylene, polypropylene, PET)

We handle various types of bio-based materials. Polyethylene and PET are derived from plant sources, while polypropylene comes from waste cooking oil (mass balance). These materials can reduce greenhouse gas emissions compared to conventional manufacturing processes. For bio-based polyethylene, emissions can be reduced by up to 70%, and for PET, by up to 25%.

Provision of environmentally friendly foaming agents

The Chemical Solutions Division sells hydrofluoroolefin (HFO) foaming agents for polyurethane, which are environmentally friendly, in Japan and the Asia region.

HFOs do not deplete the ozone layer and have a Global Warming Potential (GWP) that is less than one-thousandth of that of conventional polyurethane foams from the previous generation. Through the sale of this product, we aim to contribute to the reduction of greenhouse gases from polyurethane insulation construction sites in Japan and Asia, thereby helping to preserve the global environment.

Provision of recycled solvents

Solvents are used in various manufacturing processes of industrial products, with an annual consumption of approximately 2 million tons, while the amount of recycled products is only about 200,000 tons per year.

We aim to contribute to the reduction of greenhouse gas emissions through the sale of recycled products.

Recycling of automotive shredder residue

Planic Co., Ltd., which is funded by Toyota Tsusho, began the production of recycled polypropylene derived from ASR (Automotive Shredder Residue) in 2023.

We sell recycled plastics sourced from various end-of-life vehicles, including Planic materials, to the mobility sector and other life materials sectors such as home appliances and logistics materials, contributing to compliance with ELV regulations and the realization of a circular economy.

Promoting the collection of end-of-life tires and waste rubber parts, and recycling chemicals and materials

We aim to achieve a 'circular economy' by establishing a scheme for both chemical and material recycling using end-of life tires and discarded rubber components as raw materials in Japan.

Support for development of materials for fuel cells and lithium batteries

Through contract testing, we propose material development solutions that are expected to reduce environmental impact.

Products derived from natural materials

We aim to achieve a 'carbon-neutral society' by utilizing natural materials such as starch to reduce the proportion of fossil fuel derived raw materials, while also focusing on the recycling of food waste and other residual materials.

Obtained ISCC PLUS certification at four locations.

Toyotsu Chemiplas has obtained ISCC PLUS certification at four locations: our Tokyo headquarters, Osaka branch, Nagoya branch, and Hamamatsu sales office.

This certification ensures that recycled materials and biomass raw materials are properly managed throughout the supply chain, including product manufacturing.

With this certification, our company is now able to handle ISCC PLUS certified products that allocate sustainable raw materials using a

mass balance approach.

As a member of the Toyota Tsusho Group, we aim to contribute to the realization of a 'carbon-neutral society' through the expansion of our handling of ISCC PLUS certified products.